Ideal for Different Applications such as Wastewater, Biomass, Food and Fruit Scraps

General

Capable of fragmenting large and solid particles, the N.Mac® twin shaft grinder is ideal for different applications such as wastewater treatment, biomass substrate handling, and food and fruit scraps.

The housing designs, channel and inline versions, allow installation into effluent channels or with flanges to prevent pipe clogging and to protect downstream equipment, such as pumps.

Your benefits:

- Shock absorption system

- Mechanical seals with quench

- Modular design of cutting units

- Optional clearing comb for fibrous materials

- Efficiency increasing side rails (flow and cutting)

- Optional extend shaft or channel version

Technique

Design Details:

- Housing for inline channel installations

- Flow rates from 50m³/h to 400m³/h

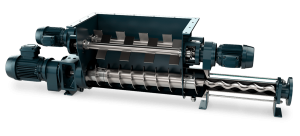

- Double Shaft technology for reduction of solid particles

- Low power installation at 2,2 kW, 3 kW and 4 kW

- Low rotation of the cutters at high torque (1:29 reduction)

- Hexagonal shaft in hardened steel

- Standard cutter arrangement 7/7 teeth

- Optional control unit to reverse direction of rotation in case of blockage

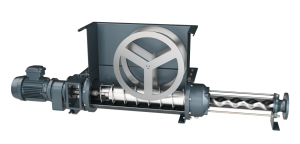

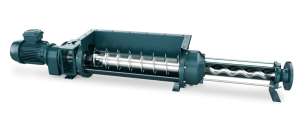

N.Mac® Channel

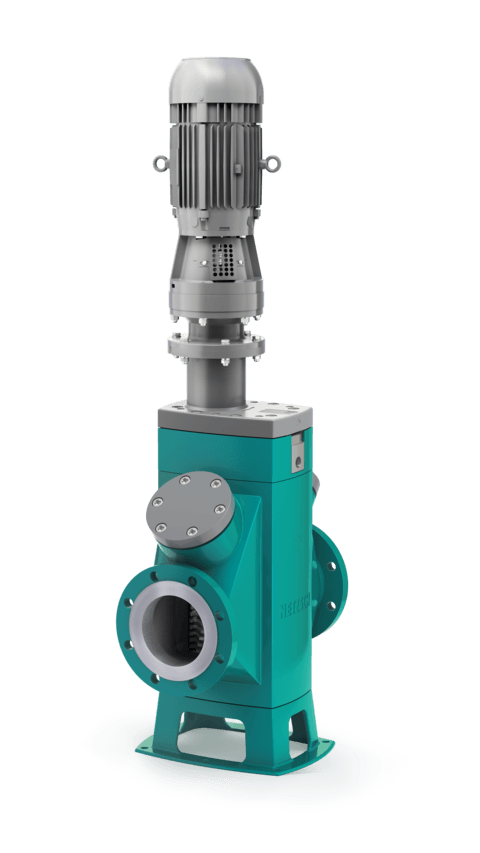

N.Mac® Inline

Applications

Among the most important areas of application are:Biogas plants, agriculture, sloughterhouses and recycling plants, canning factories, industrial kitchens, sugar factories.

Accessories

Cutters: Specific cutter geometries for each type of solids facilitate the particle reduction process. To reach the required particle size the different cutters with 3 to 11 teeth may be combined accordingly.

The cutters are thermally hardened to increase resistance and sharpness assuring reliable grinding of the toughest solids.