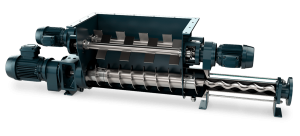

Combines the Cutting and Conveying of Large Pieces in Many Industrial Sectors

Conveying and cutting in one process step without expensive additional equipment, this is exactly what the NEMO® BO/SO hopper pump with integrated cutting device makes possible. With the progressing cavity pump, for example in the food industry, large solids such as pieces of fruit or vegetables can be easily and quickly chopped and pumped for further processing.

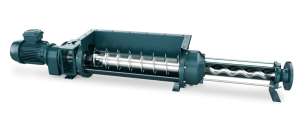

The NEMO® BO/SO progressing cavity pump with hopper and coupling rod with feeding screw and force-feed chamber is employed in almost all branches of industry to provide continuous, pressure-stable, gentle and low-pulsation conveyance.

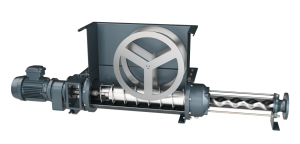

Feeding through Hopper with Cutting Unit

The hopper housing with cutting unit guarantees optimum feed of chunky medium into the conveying elements. If the medium passes the force-feed chamber with the cutting unit the larger fruits and vegetables are cutted immediately. This unit consists of a rotating knife with three blades and a variable number of stationary knives adjustable to the size and consistency of the particles.

Optionally the pump can be equipped with an additional cutting unit at the discharge flange of the pump. With its perforated disc and rotating knife it allows for further fine definition of the particle size.

As any other NEMO® progressing cavity pump also the BO/SO pump has the ability to dose the conveyed media in proportion to rotation speed. In block construction with a flanged drive, this pump is particularly compact and economical. It is also available with bearing housing for a wider range of drives.

Features of the pump

- Hopper housing with rectangular inlet flange and feeding screw with force-feed chamber to provide optimal feed for slowly flowing and pasty media into the conveying elements

- Continuous low-pulsation conveyance una ected by fluctuations in pressure and viscosity

- Conveyance volume in proportion to rotation speed with high dosing precision over a broad rotational-speed range

- High pressure capability without valves

Features of the cutting units

- Cutting unit inside the forcefeed chamber consisting of a rotating knife with three blades and a variable number of stationary knives adjustable to the size and consistency of the particles

- Cutting unit at the discharge flange with perforated disc and rotating knife allowing for further fine definition of the particle size

Advantages

- Variable modular system for optimum conveyance and cutting

- Robust and compact construction

- Constant flow

- Ease of service

- Replacing additional machinery