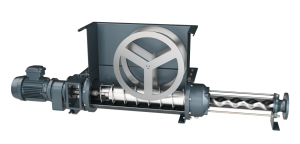

The Solution for Highly Viscous and Crumbly Substances that Tend to Bridge

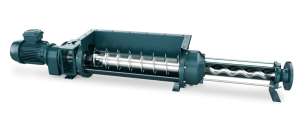

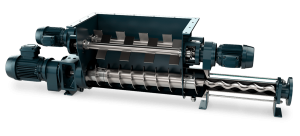

The NEMO® BF hopper-shaped progressing cavity pump with aBP-Module® to prevent bridging is used in all branches of industry for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed, especially for highly viscous, compacted and crumbly media.

For optimum product feed into the conveying elements, the pump housing is designed with an enlarged, rectangular feed hopper and conical force-feed chamber as well as a special coupling rod with patented, positioned conveying screw. The additionally attached aBP-Module® – asynchronous Bridge Preventing – consists of a top shaft with two internal spoke wheels. These create «moving shaft walls» which exert a shearing effect on the medium. This reliably prevents bridge formation in the pump shaft. This also ensures the smooth conveying of solid-loaden, shear-sensitive, abrasive, adhesive, thixotropic or dilatant as well as lubricating and non-lubricating materials that have a tendency to bridge. The NEMO® is particularly compact and economical in block construction with flanged drive.